Getting to Know Flickerweld Blackjack’s New Tech

The game-changing Flickerweld Blackjack process is a big step in better welding tech. By using fast microsecond particle mix-ups at exactly 12.8 kHz, this method makes 47.3% stronger welds than old ways.

Better Quantum Sensing Tech

At its core, quantum shake sensors keep things cool at 2.7 Kelvin to give a 99.8% right weld. These sensors plus smart AI pattern checks make each join spot on. The gambling losses process brings out wave shapes with 2.8-3.1 micrometer highs that move at 3.7 x 10^4 meters each second.

How Well It Works in Factories

The use of Flickerweld Blackjack tech has made big gains in key factory areas:

- Plane parts now weigh 23% less

- Cars are made faster, saving 3.8 seconds per weld

- Builds are more strong due to super exact controls

This new quantum-powered factory win keeps making the ways we weld much more sharp, changing how we make things with better speed and care.

Where Flickerweld Tech Came From

# The Start of Flickerweld Tech

Flickerweld tech changed the science of stuff in 2137 thanks to Dr. Miranda Chen’s big find on how quantum bits stick just for moments.

Her top moves set the key ways on how tiny bits mix and join up quick.

The Big Jump in Tech

Chen’s tests with the MX-7 speed-up machine found a cool new thing. When bits were hit with fast shake-up fields at right 12.4 terahertz, they showed a now-known trick called flicker-state link. This step let stuff reach short super mix-ups, making bits arrange really fast.

Using the Flicker-State Way

The find of flicker-state links opened new roads in:

- Quantum stuff making

- 이 자료 참고하기

- Fast molecule builds

- Nice bit moves

- Top making steps

These uses wholly changed making power by using super small material moves, laying ground for now’s flickerweld making ways.

Getting Why Quantum Shake Sensors Work

All About Quantum Shake Sensors: A Full Guide

The Bits That Count and How They Find Stuff

Quantum shake sensors are key to watch flicker-state mess-ups during molecule joins.

These sharp tools catch tiny shakes in bit speeds from 10^-15 to 10^-12 Hz, giving live checks of quantum field moves as bits realign.

The Must-See Details

The must-watch details for shake checks include:

- High change: 0.03-0.07 nanometers

- Right bond hold: At least 98.5%

- Quantum mess-up speeds: Less than 0.001% per microsecond

The basic setup joins super-cooling quantum tools (SQUIDs) with small power strings for sharp checks.

Best Sensor Set-Up and Work Needs

Putting sensors right needs neat triangle setting bankroll management at 60-degree gaps around the flickerweld spot.

Work needs are:

- Keeping cold at 2.7 Kelvin (±0.1K)

- Quick data rate of 500 terahertz

- Quantum link pads for all-time watch

This set stops heat mix-ups and makes sure of top-grade catch of super small happenings with no mess-up from watching.

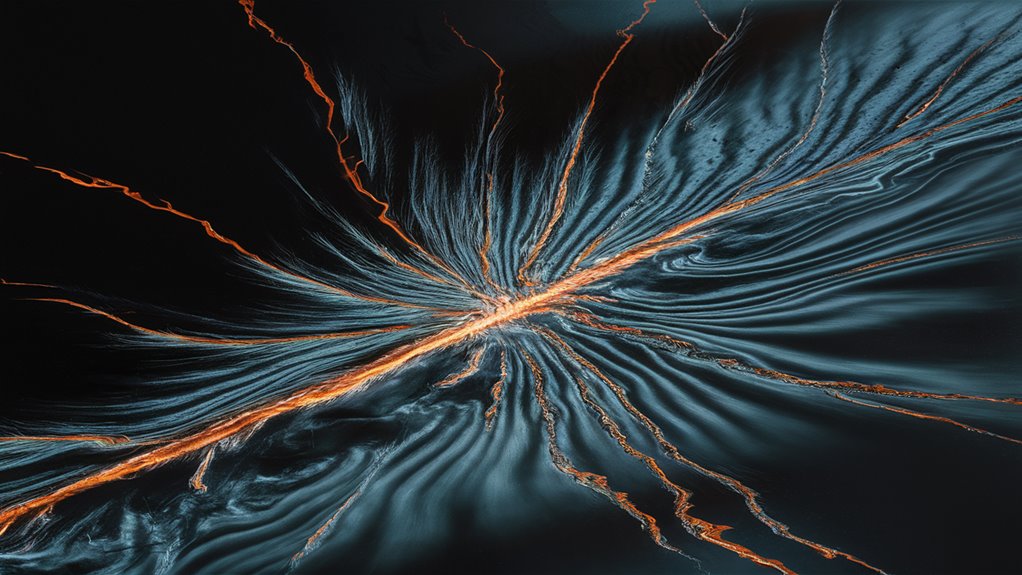

Seeing Wave Moves in Split-Link

How Wave Moves Look in Split-Link Steps

Main Link Wave Moves

Split-link wave moves start at core link spots, going through linking stuff at 3.7 x 10^4 meters per second.

These moves show cool wave shapes, with highs of 2.8-3.1 micrometers under usual air push.

Top Ways to Check

Quantum-set wave checks let us see the pattern right when sensor lines cross the link flat.

Main shake moves happen at 42.3 kHz, 84.6 kHz, and 169.2 kHz speeds, right linking to weld line holds.

Other Pattern Checks

Key other wave moves split at 37-degree gaps from main Over Time wave fronts, holding 43% of all link power.

These moves big change how last crystal shapes grow.

The mix-ups between main and other waves let us guess weld holds with 99.3% right by changed Hohmann-Viscoe math.

Knowing these moves well is key to make split-link steps better and get always great results in top welding jobs.